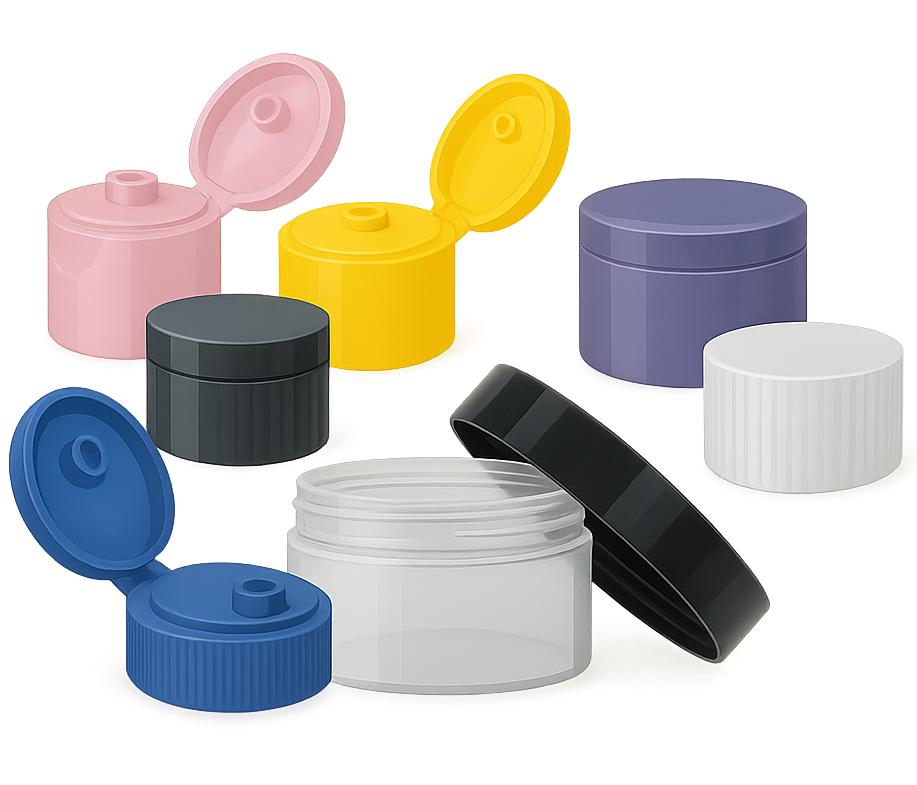

Custom plastic packaging for care, beauty, and health products.

Beauty & Personal Care & Pharmaceutical Products

Discover our diverse range of high-quality packaging solutions tailored for the beauty, personal care, and pharmaceutical industries. From elegant bottles and jars to precision applicators, secure caps, and specialized closures, each product is designed to preserve integrity, ensure safety, and enhance user experience. Whether you're launching a cosmetic line or a medical-grade product, our collections combine functionality with refined aesthetics to meet the highest standards of innovation and sustainability.

Bottles & Vials

Discover our wide range of bottles and vials for cosmetic and medical use.

→ Learn MoreHDPE Blowing

HDPE blowing is a manufacturing technique used to create hollow packaging such as bottles, flasks, and jerrycans. It involves heating high-density polyethylene, extruding it into a tube shape, and then blowing air into it to match the mold's shape.

Valued for its strength, lightness, and recyclability, HDPE is ideal for the cosmetics, pharmaceutical, food, and industrial sectors. It offers a reliable and sustainable solution for high-quality rigid packaging.

PET Blowing

PET blowing is a process used to manufacture lightweight and transparent packaging, such as bottles for beverages or cosmetic products.

It involves heating a PET preform and then blowing it into a mold to give it its final shape. This process is appreciated for its speed, precision, and the visual quality of the finished products.

Plastic Injection

Plastic injection, on the other hand, is used to produce solid and complex parts by injecting molten plastic into a closed mold.

Ideal for caps, closures, or technical components, this method offers excellent repeatability and great design flexibility.

Together, these technologies cover a wide range of rigid packaging needs, combining performance, aesthetics, and industrial efficiency.

Committed to Sustainability

We are dedicated to minimizing our environmental impact through sustainable materials, efficient processes, and eco-conscious innovations. Our goal is to deliver high-quality packaging solutions that are as responsible as they are reliable.